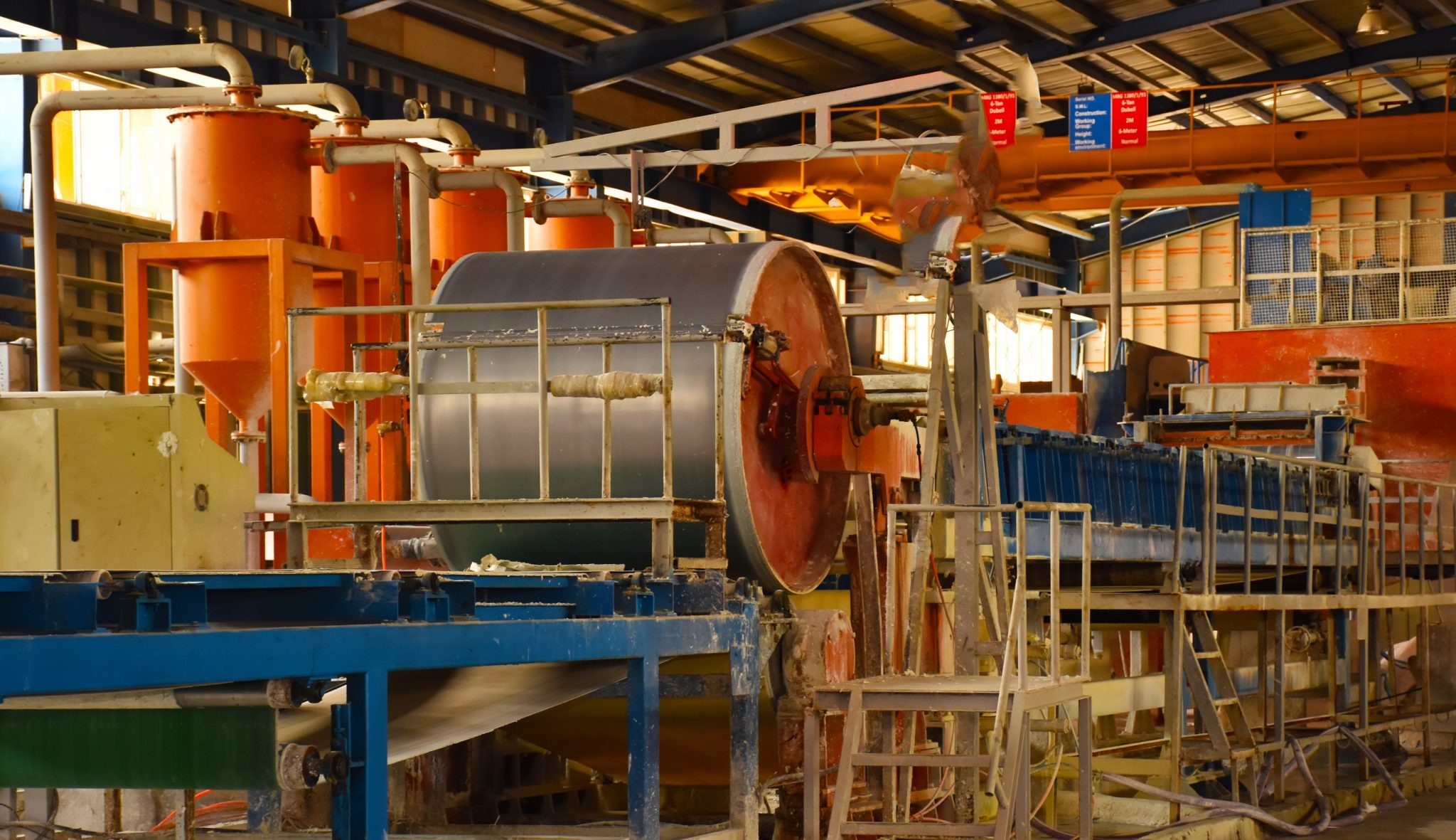

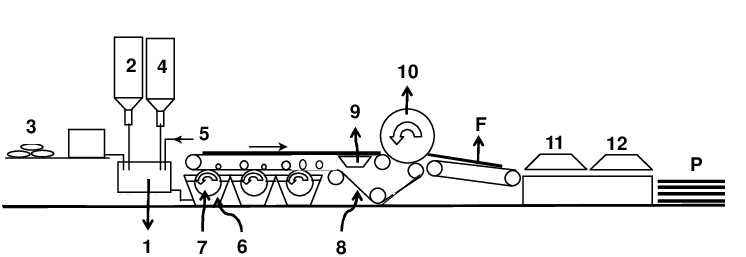

Use the Hatschek method

Description of the process of manufacturing fiber cement board

The fibercement board consists of silicon, silica, and water, which is made by the fiber using the Hatschek method. This process was originally used to produce composites, but is now for something that can be used as a substitute Asbestos used.

فارسی

فارسی  English

English